Life Cycle Management Program

Many NZ companies have the ambition to operate in an environmentally sustainable way. However, the reality of implementing a structured approach to do so can be a challenge.

Manufacturers and Exporters are under increasing pressure to understand, document and improve their environmental footprint. However, not all companies are aware of their performance and ways to structure and integrate sustainability into the product development process.

Landcare Research initiated a research program to look into ‘Design for environment’ activities within New Zealand companies. The objective was to gain an understanding of the current landscape product development and the role of life cycle thinking and management within.

EXPERTISE

Research & Testing

Manufacturing

Commersialisation

Business Development

GAINING INSIGHT

Landcare Research asked us to help them achieve the first phase of their research program – assessing the current state of Life Cycle Management (LCM) implementation at five selected NZ companies.

Through a series of interviews, site visits and review of company literature (websites, marketing material and documentation), we aimed to get answers to two overarching research questions.

- What are the benefits and costs of implementing LCM in manufacturing companies?

- What are the enablers and barriers to implementation of LCM in manufacturing companies?

The interviews centred around a questionnaire that looked into the drivers of incorporating Life Cycle thinking into R&D processes, and the opportunities (enablers) and potential risk (barriers) it can bring.

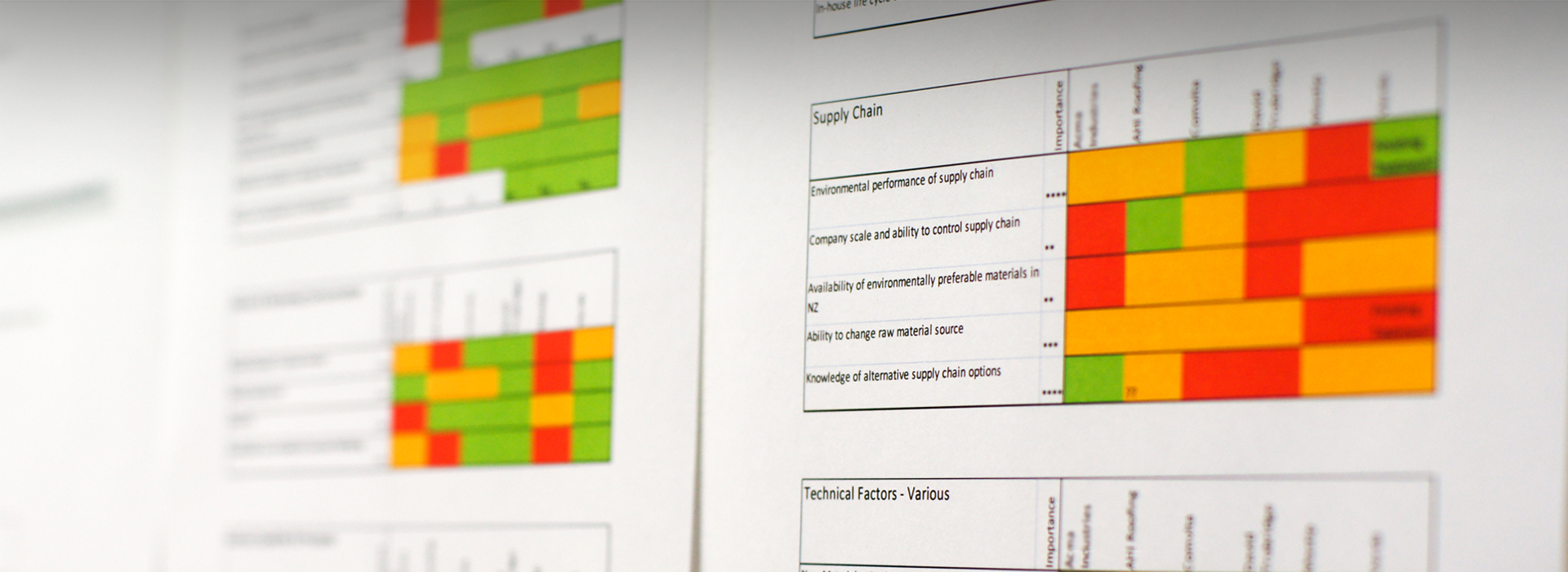

SIX AREAS

After completing the interviews and assessing all documentation, it became clear that the enablers and barriers fell into six themes:

- Culture and Organisation

- Market and Marketing Communication

- Business Capability and Processes

- Life Cycle Knowledge and Inventory Data

- Supply Chain

- Technical Factors

Each theme contains a subset of more specific area related factors that have their level of importance compared to each other. The factors were rated as a barrier or enabler for each company, creating a good overview of the bottlenecks in a companies performance.

“LCM is more than simply recycling, it’s about changing business processes and ensuring sustainable access to valuable overseas markets.”

– Dr ANTHONY HUME – LANDCARE RESEARCH

MAIN FINDINGS

The researched companies had varying levels of understanding if they integrate LC within their R&D activities, as well as varying drivers to do so. However, there are shared insights that drive success.

Embed sustainability in your company culture

It is essential to have a company culture, or parent company culture, that includes sustainability values. Moreover, communicating these values internally and externally are crucial – even if even feel environmental issues do not drive your customer base.

LCM is a smart business choice

LCM can improve efficiency in the use of raw materials and energy and reduced waste – promoting a better environmental outcome. The efficiencies also result in cost savings for manufacturers and improved decision making to meet customer demands on environmental impact.

Have internal ambassadors

Having senior management that has a progressive, enthusiastic and engaged with LCM or environmental issues will go a long way on the road to success.

Ensure knowledge

Make sure there is a good understanding product life cycle environmental issues and integrate life cycle thinking across your (R&D) team. It should be well understood and part of the day to day business.

Don’t forget your supply chain

Environmental performance of the supply chain is viewed as a critical factor to implement LCM principles. The ability to make changes to your supply chain will be a dominant enabler or barrier to success. The more you can influence change, the better, and this crosses over to manufacturing, transport, and end-of-life management.

Structured design and development processes

Include a life cycle thinking approach in your design and procurement processes from the start. This way LCM will become a fundamental part of your development. Any presence of existing systematic business processes in other areas may act as enablers to implement other initiatives such as LCM. In particular, close relationships exist with lean manufacturing initiatives responsible, chemical care initiatives and environmental monitoring/reporting.

Huge thank you to the participating companies. Not only did they invest substantial time and effort, but they also provided us with valuable insights.

David Trubridge – Furniture/Object/Lighting

Mastip – Hot Runners/Injection moulding

AHI Roofing – Steel Roofing

Verda – Outdoor Living/Timber Products

ACMA – Polyurethane Products/Healthcare

Comvita – Natural Health/Functional Food