Insights by Adidas Future Team through 4D Innovation

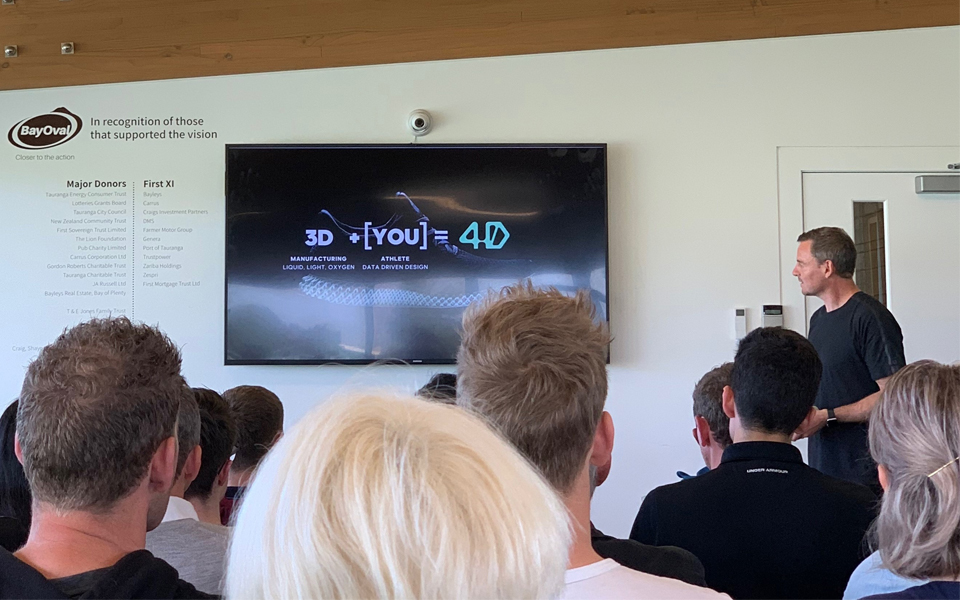

I had the pleasure of hearing Mark Henderson from Adidas speak at the Sports Performance Innovation Forum, which was hosted by Virtuosity as part of the Groundswell festival of innovation.

Mark hails from Tauranga, and like most kiwis, after university, he went on his OE to see more of the world. He worked in a range of jobs, including shaping surfboards and counting cars parked in bus lanes in London, before landing an internship at Adidas 17 years ago. Mark dove in wholeheartedly, and as they say, the rest is history. He is now the Senior Engineering Director for the Future Team, based in Portland, Oregon, where he leads a team of talented engineers, working 3-7 years out on game-changing ideas.

Mark presenting at the Sports Performance Innovation Forum

Technology + Athlete = 4D Innovation

Adidas take a 4D approach to design, where 3D Technology + Athlete = 4D Innovation. The key focus areas of technology are materials, manufacturing methods, mechanical testing, and computation for faster iterations and design optimisation. However, ultimately, it’s all about the athlete – and getting them products in hand for feedback and iteration.

Data

Adidas utilises low res and high res data in the pursuit of furthering human performance.

Low res data can be in the form of data mining through social media, such as Strava and Instagram. Interestingly, this has informed Adidas that people are actually using their product differently in different cities.

An example of high res data is Digital Image Correlation. This is a technique that has come from the materials testing industry. It is a way to measure strain using a visual system. You take two cameras and put a random speckle pattern on the object, and you measure the strain. Adidas took one of their shoes, used a sharpie to speckle it, and were able to use this technique to learn about the direction of the strain. This was used to optimise stretch for fit, but also to optimise reinforcing for a range of different movements. This technology has been utilised across footwear and sports bra design.

This is James Harden in a speckle shoe, which was only intended for use in the Adidas lab. He loved the shoes – took them home with him, and they appeared on the court the following night!

Form follows function

With the development of an exceptionally performing “boost” foam material for midsoles, the Adidas team had the challenge of encapsulating this technology into a desirable aesthetic. After struggling to hide the look of the foam, the design team made a stand to embrace it for what it is and allow the form to follow the function. This has proven to be a real lesson for Adidas in accepting the technology for what it is. It is a great success, measured by the fact that most of the staff at Adidas wear the shoes, not to mention Kanye West’s endorsement. Adidas produces 400 million pairs of shoes a year, and over 100 million of them are “boost” shoes.

The Adidas Boost shoe and foam.

What’s next?

Tuning shoes for the individual is next. A wide variety of people wear size 9 shoes. However, that does not necessarily mean they want to be wearing the same shoe, it should be tuned for the individual.

Adidas started looking into 3D lattice structures and discovered Carbon, a 3D printing startup in the Bay area (SF). They were able to print midsoles in 20 minutes, bring down costs dramatically, and use a light-activated polymer that was starting to meet performance specifications. Adidas jumped onto the project and here is a look at the results so far:

Adidas – 3D lattice structures by Carbon 3D printing

The real key to success is Adidas’ ability to do the design and engineering computationally. They can optimise designs virtually before actually having to make them. With this data-driven design, they can also take data from athletes and use it to drive the data that goes into optimising the structure. Athlete insight + technology = innovation.

Circular Economy

Like many other leading companies, Adidas is making efforts to go circular. A good example is the Parley collection – where plastic trash from the ocean is upcycled it into some of their footwear and sportswear. The marine plastic waste is collected from coastlines, baled, and sent to Parley supply chain partners, where it is shredded and reworked to become high-performance polyester yarn. This is then used to create Adidas x Parley sportswear.

Adidas have also made the commitment to end the use of virgin polyester and shift entirely to recycled polyester by 2024.

And one of their latest projects is a high-performance running shoe made entirely from a single material, virgin thermoplastic polyurethane (TPU). It’s called the Futurecraft Loop, and the different TPU components are fused together with heat, requiring no glue for construction. By sticking to one material, the Futurecraft Loop can actually end up in the recycling stream, unlike many if not all shoes around.

The Adidas Futurecraft Loop – 100% recyclable

Thanks to Mark, for taking the time and sharing some stories and insights from the Future Team at Adidas!

Want to read more on creativity, design, product development and innovation? Go to our Six Lenses Blog.

Comments